PRESS RELEASE

CIRCULAR SPORTSWEAR FROM BEANS: PROJECT RECEIVES EU FUNDING

FOR RELEASE: 15/09/2022

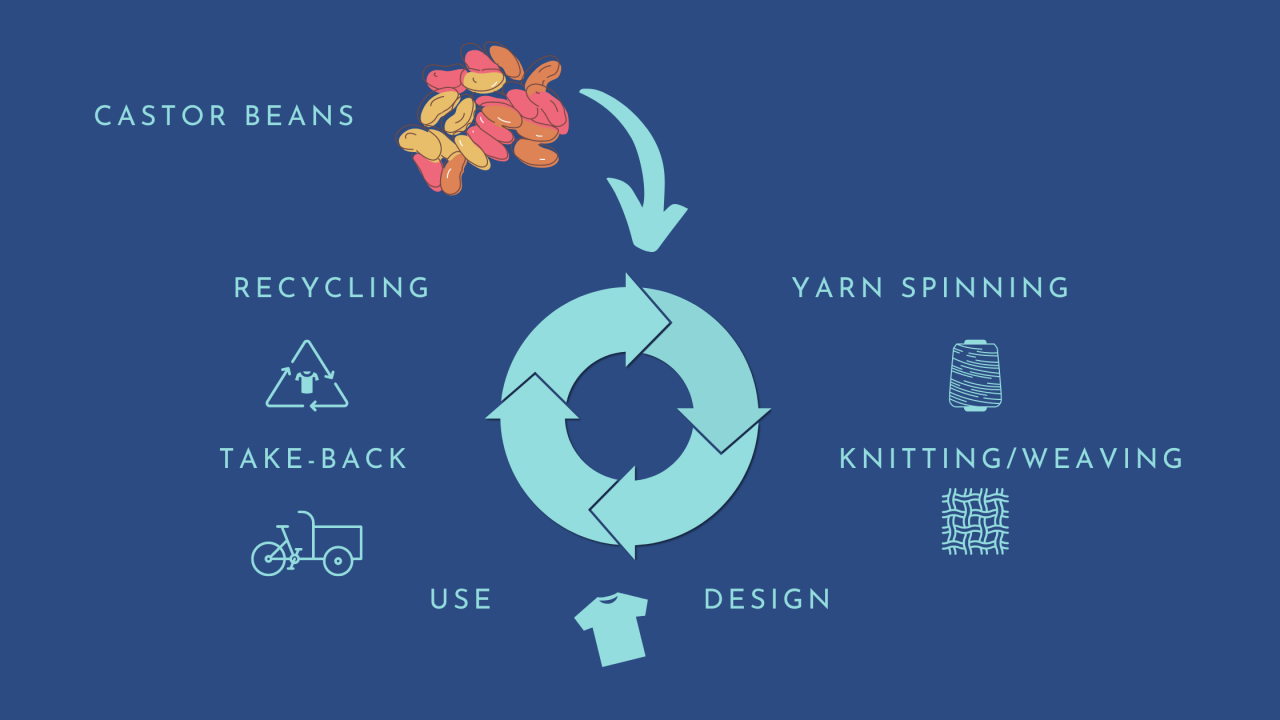

Circuvate and The Good Factory are proud to present their joint project; BioAce, a dedicated circular system for 100% bio-based performance sportswear. Funded as part of the S4 Fashion project with the contribution of the EISMEA Programme of the European Union, the collaboration aims to realise the potential of a circular system for performance sportswear consisting of 100% bio-based and mono-component garments, which will include take-back of the garments at their end-of-life and their use in fibre-to-fibre recycling, in order to reduce overall emissions, waste and water compared to the production of garments made from virgin, petroleum-based synthetic fibres. The 10,000 EUR funding will be used to validate key steps and evaluate the feasibility of the circular system, including the production of a prototype garment, the recycling of the textile scraps from the manufacturing, and an evaluation of the overall impact of the circular system.

This collaboration brings together the expertise of Circuvate (Germany), a technical consultancy specialised in circular materials, recycling and impact analysis in the fashion and textiles sector, and The Good Factory (United Kingdom), experts in sustainable garment and textile design, development, and manufacturing.

Samantha Taylor, Founder of the Good Factory explains the benefit of the BioAce approach for brands: “It’s all too easy to unintentionally miss ESG targets within the production of sports apparel. We are working directly with brands to develop sportswear that performs well under intense physical activity whilst reducing environmental impact. Through this project, we will show that you don’t have to compromise performance for sustainability. Furthermore, we will work directly with trusted and verified partners with high standards of labour practice. Traceability and transparency will be an important part of the BioAce service.”

Specifically, the project aims to explore the use of a 100% bio-based polyamide (PA 10,10) due to its similar technical features to traditional petroleum-based synthetics such as PA 6 and PA 6,6 (also known as Nylon) which are used in sportswear for their hydrophobic, hardwearing, and antibacterial and wicking capabilities. While traditional polyamides use oil as the feedstock, PA 10,10 uses a renewable source in the form of castor beans, which grow without the use of pesticides and with little water. Data shows that the use of such bio-based polyamides can reduce the carbon footprint by 55% compared to the production of virgin petroleum-based fibres such as PA 6,6. BioAce intends to reduce that further by exploring the development of recycled bio-based yarns, initially from factory cutting waste.

Dr. Ashley Holding, Founder of Circuvate explains further: “In most cases, bio-based materials can and should be recycled. Although the environmental impact of transforming castor beans to fibres is more favourable than conventional petroleum-based synthetics, we can reduce the carbon impact of the overall system ever further by incorporating recycled and bio-based content. Additionally, the way the system is envisaged ensures that the BioAce garments are designed with the end-of-life in mind and paired with the future take-back and recycling system means that it will be a fully closed loop, with minimal waste – which also avoids the use of petroleum resources.”

The project will end in Summer 2023. Apparel brands or textile manufacturers with existing PA 10,10 fabric waste are encouraged to get in touch, as well as brands who are interested in developing circular bio-based performance sportswear as part of the BioAce system.

— ENDS —

Contact Details

Media enquiries: enquiries@bioace.eu

Website: http://bioace.eu

Circuvate

Dr. Ashley Holding

ashley.holding@circuvate.com

The Good Factory

Samantha Taylor

sam@thegoodfactory.co.uk